admin

admin  2021-03-19 07:31:18

2021-03-19 07:31:18

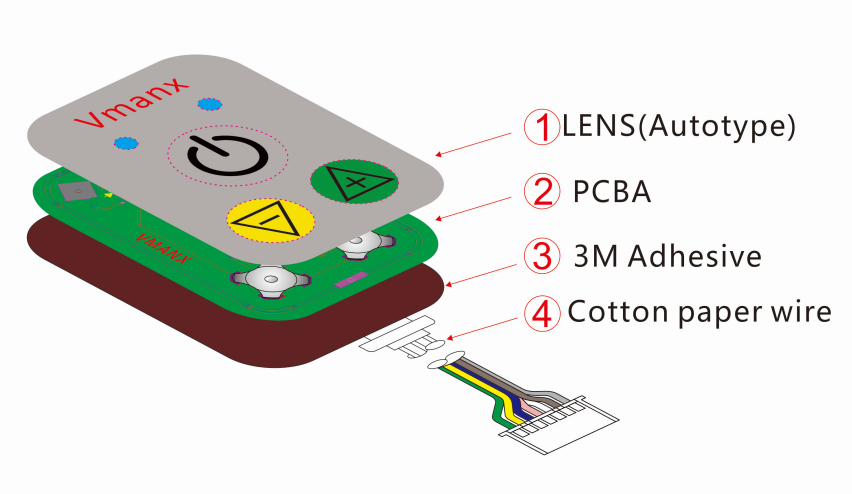

The existing membrane switch adopts a three-layer structure, including an upper conductive layer, an insulating layer, and a lower conductive layer. Both the upper conductive layer and the lower conductive layer are provided with trigger parts, which are respectively connected to the positive electrode and the negative electrode. When the membrane switch is pressed , The trigger parts on the upper and lower conductive layers contact to make the positive and negative poles conduct, and the switch conducts. The upper conductive layer and the lower conductive layer need to be provided with circuits at the same time to realize the switch conduction, which makes the production process of the membrane switch complicated and the cost is high. Moreover, the existing circuits are generally formed by printed silver wires, and jumpers are arranged by setting up connecting wires above the circuit board. In order to avoid short circuits, an insulating layer must be provided between the circuit board and the jumper. If the insulating layer is not set In place, the circuit board is prone to short-circuit or poor contact.

On all kinds of mechanical equipment, we often see membrane switch buttons. It uses small buttons to control the operation of the entire mechanical equipment. The appearance of membrane switch buttons is somewhat different from that of ordinary household remote control buttons. Only the characters are different, but there are actually some differences in the production process.

Spraying laser engraving is a common production process for controller silicone keys, and the reasons are as follows.

1. Silicone button manufacturers stated that most of the controller buttons used on mechanical equipment have LED lamp beads at the bottom, and the surface of the button needs to have the requirements of light transmission, and the light transmission of the laser engraving process is excellent.

2. The spraying laser engraving process is more advanced. The spraying process can make an ordinary silicone button into a high-end button with good texture and feel. The laser engraving process can make the characters have a concave and convex feeling and permanent wear resistance. These advantages make the silicone button more effective. The overall performance is greatly improved in an instant.